01

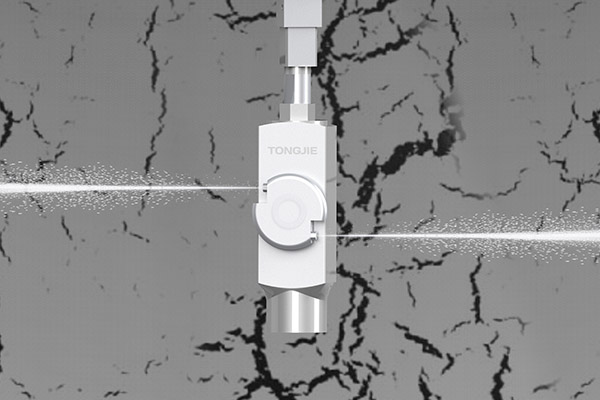

Tank and Kettle Cleaning

The pressure level can be selected according to the composition of the scale and the cleaning requirements, without causing physical damage and keeping the reactor surface smooth, so that the scale is not easily attached to the reactor. The pressure of the high-pressure water jet is used to break up the hard scale on the inner wall of the reactor and on the surface of the stirrer, so that it is completely stripped and removed.

02

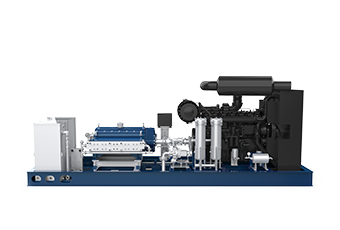

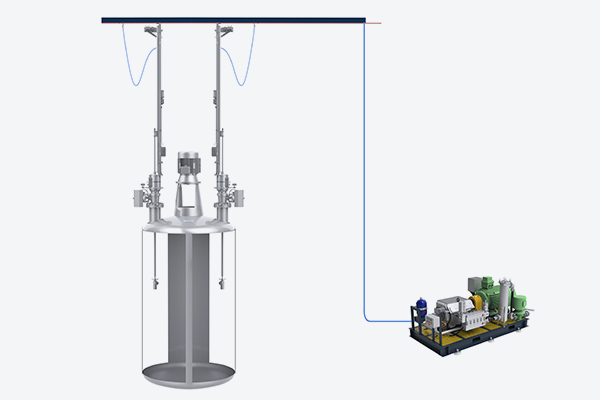

Fully automatic cleaning system for polymerization kettles

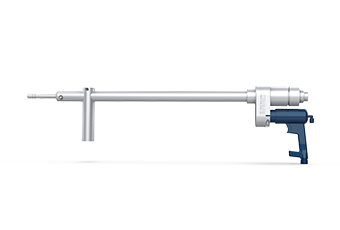

Fully automatic cleaning system for reactors, kettles, tanks and other tank vessels. Pneumatic drive assembly with a stroke of up to 6500 mm, rodless cylinder design, with support for high pressure lance and tank cleaning head.

The system is controlled by a PLC or can be equipped with a local control panel, the cleaning position and duration can be selected by the customer and can be connected to a DCS system for process cleaning.

03

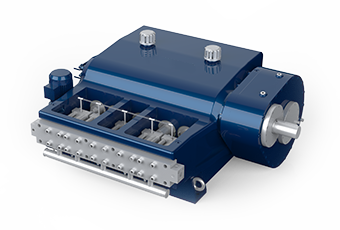

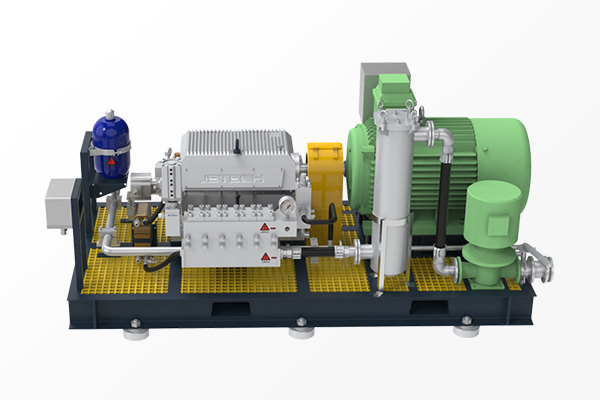

High pressure pumping unit

Automatic control of the unit, independent of the operating conditions, safe, stable and reliable operation. Local operation panel and PLC control box for high-pressure pumps and cleaning units, with necessary electrical components, start and stop indicators and fault lights, emergency stop button. The low water pressure alarm function effectively prevents system damage due to filter blockage or insufficient water supply pressure. Pneumatic pressure regulating valve and TYD safety relief valve using the American JETECH can achieve stepless pressure regulation, with double safety protection function.