01

Coal seam water injection

Coal seam water injection effectively reduces the amount of dust produced and dust concentration during the production shift, and is an effective way to improve the working environment for personnel and increase the productivity of the working face. The addition of active wetting agents to the water injection process enhances the permeability of water in the coal seam and solves the problem of water not penetrating into the microfractures of the coal body, making the dust reduction effect more desirable. This effectively reduces the concentration of gas during the production shift and has a certain effect on the abatement of protrusions.

02

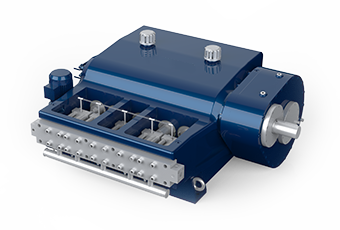

Spray dust reduction

Advanced dust reduction mechanism, good dust reduction effect. The dust collector is easy to install and does not affect the normal work of the roadheader after installation. The dust collector itself is anti-smashing and can ensure long-term, reliable and stable operation of the dust reduction system. The original spiral tooth high-pressure atomized water core nozzle not only improves dust removal efficiency but also solves the problem of nozzle blockage. Automatic control of the water tank with internal filtering device to ensure smooth flow paths for the high pressure pump and atomizing nozzles.

03

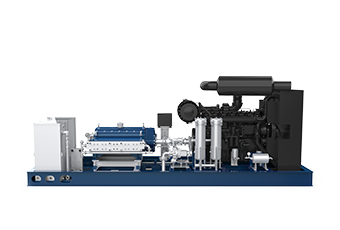

Topsides installation

The hydraulic fracturing technology has low power disturbance, high safety and simple management, which can be referred to the management of high pressure lines on hydraulic supports, large control range in a single hole, small volume of work, the ability to achieve deep fracturing at long distances as needed, large control distance, basically no damage to the support, good operating environment and low cost.

04

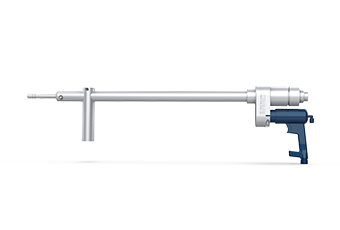

High pressure water slitting

Extraction of coal seam gas using hydraulic slitting is a fundamental prevention and control measure to avoid the occurrence of coal mine gas disasters. The hydraulic slitting technique causes the coal body to relax, depressurise and rupture after the slitting to increase the permeability of the coal seam exponentially or dozens of times, and then extracts the coal seam gas, turning the gas seam into a low or no gas seam and fundamentally preventing disasters from occurring.