01

Cleaning or renovation of aircraft runways, storage areas, etc.

Removal of rubber and graphic layers from roads, landing strips, etc.

02

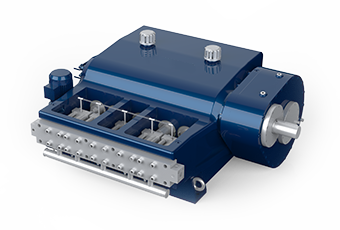

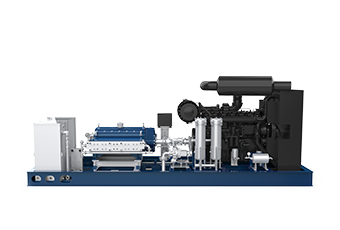

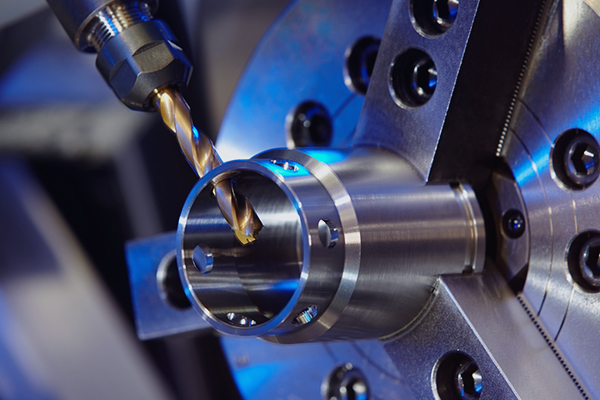

Cutting of metals and alloys

High-pressure water jet technology can cut, punch, strengthen and deburr special structures, difficult-to-machine materials and composite parts targeted at aero-engines, providing an efficient and cost-effective processing method for aero-engine manufacturing. These materials, when processed by methods such as mechanical cutting or laser cutting generate heat, causing damage or deformation to the material, further affecting the strength of aircraft, rockets and other vehicles.

03

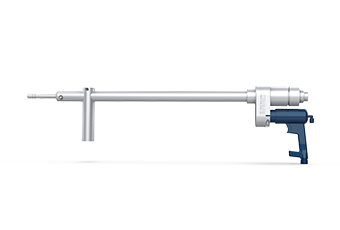

Removal of solid propellants from missiles and rockets

Propellants have a high impact and friction sensitivity, are flammable and explosive, and are difficult to remove by mechanical cutting; manual cleaning with a hand-held knife is difficult, inefficient, ineffective and extremely dangerous. The application of water jet technology to the elimination of solid propellant charges in missiles and rockets has been successful, and has achieved excellent economic and social benefits, making the long-standing problem of removing solid rocket motor charges, which is extremely dangerous, completely solved.

04

Product cleaning for the aviation industry

Cleaning and refurbishment of missiles, aircraft painting and pre-assembly processes, composite moulds, paint removal from special aircraft, engine carbon cleaning, maintenance cleaning (especially in the landing gear - wheelhouse area), paint removal from aircraft casings, runways, storage areas, etc.